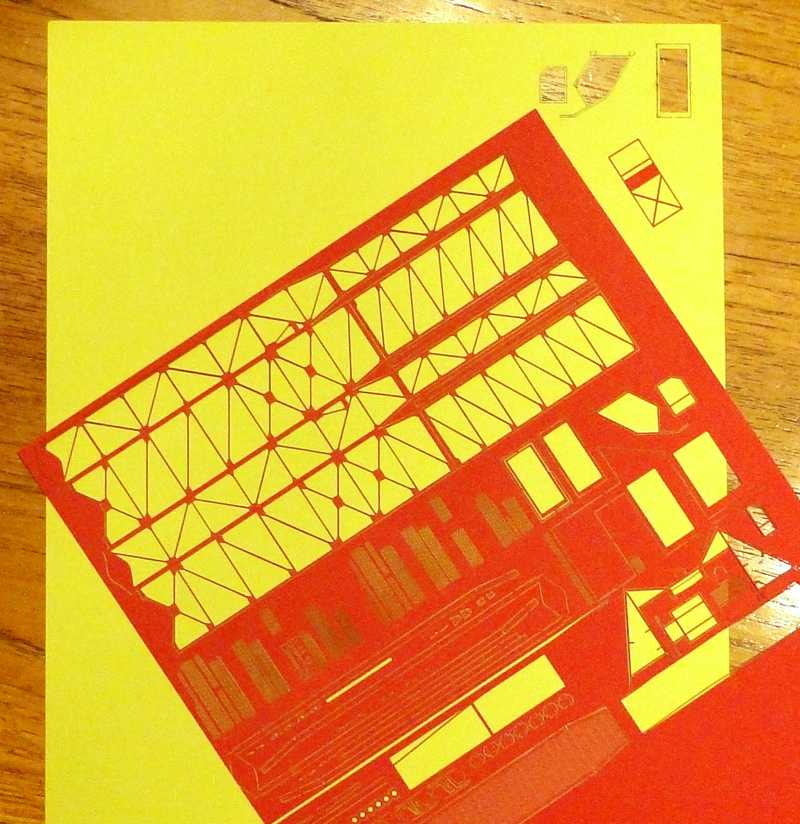

Testing laser cut

- Mischa

- LUT model

Time for a bit of dreams from the future.

Command Module Service Arm laser cut parts

Yes. The last weeks have been quite exhausting *ggg*

It all began with a call from a gentleman I did not know, whom a friend of mine referred to me. The man in question lives almost around the corner and has a gigantic laser cutter weighing 700kg in his cellar. He found out that maybe I would be interested in this technology, and he would be very happy about a visit, maybe it could develop to mutual advantage, a win-win situation, so to speak.

Well I definitely was interested !

The specifications, however, were then quite demanding - BigLaser understands CorelDRAW directly, but the thing actually cuts, engraves and carves the lines as they are drawn. That means making remaining bars by simple overlaps does not work. The lines actually have to be interrupted. And that's very, very tedious, which is why it took a while until I had the first parts of Swingarm #9 halfway laser-capable. This afternoon was all about experiments - Thomas had hardly any experience with paper, and I had no experience with lasercutters, so the conditions were perfect *ggg*. But the quality of the cut is simply stunning. With the naked eye, you don't even really see any traces of smoke on yellow paper, and the cut is simply perfect.

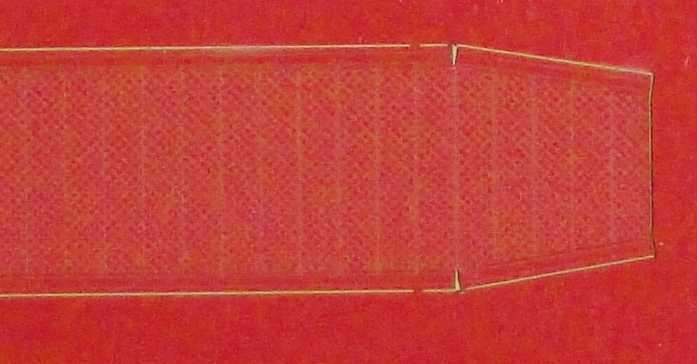

Command Module Service Arm Floor part

Fascinating what the engraving technique achieves - here the original diamond pattern of the treadplates, the photo doesn't really show it, but the tilting effect is sensational.

So, before the euphoria spreads everywhere, the damper comes now. The price. Yo. The minute costs 1,5 EUR. For the above sheet the cutter needed after numerous optimizations approx. 20 minutes. Interestingly, the cutting goes quickly, what takes is the engraving. And there is a lot of engraving - lettering, adhesive markings and and and and. The sheet metal corrugation takes about 3 minutes. Thomas has promised to sleep about and be very creative in pricing because he likes the project.

And I need some input from you now. For example, would you get along if the sheet layout of the cut sheets omits the part numbering and makes it available via PDF? This would easily reduce costs by half to a third. The cutter loosely digests A0 sheets, which can then be cut to A3. I could take the proven cutting economy to the extreme, and if I limit myself to the delicate parts, perhaps half an A0 sheet would be required per kit. Well. Anyway a lot of opportunity to ponder *ggg*